Stainless steel coils are a versatile and essential component in the automotive industry. They are used in a wide range of applications, from body panels to exhaust systems, and provide numerous benefits that make them the material of choice for many manufacturers. In this article, we will explore the versatility of stainless steel coils in the automotive industry and how they contribute to the performance and durability of vehicles.

Benefits of Stainless Steel Coils in Automotive Applications

Stainless steel coils offer several key advantages that make them ideal for use in the automotive industry. These benefits include:

- Corrosion Resistance: Stainless steel coils are highly resistant to corrosion, making them ideal for use in harsh environments and ensuring the longevity of automotive components.

- Strength and Durability: Stainless steel is a strong and durable material that can withstand high temperatures, pressure, and impact, making it perfect for use in demanding automotive applications.

- Lightweight: Despite its strength, stainless steel is a lightweight material, which helps reduce the overall weight of vehicles and improve fuel efficiency.

- Aesthetic Appeal: Stainless steel has a sleek and modern appearance that enhances the visual appeal of automotive components, making them popular among consumers.

- Recyclability: Stainless steel is a sustainable material that can be recycled and reused, reducing the environmental impact of automotive production.

Applications of Stainless Steel Coils in the Automotive Industry

Stainless steel coils are used in a wide range of automotive applications, including:

- Exhaust Systems: Stainless steel coils are commonly used in exhaust systems due to their corrosion resistance and high temperature tolerance, making them ideal for withstanding the harsh conditions of engine exhaust gases.

- Body Panels: Stainless steel coils are also used in the manufacturing of body panels, where their strength, durability, and aesthetic appeal make them an excellent choice for automotive designers.

- Springs and Suspension Components: Stainless steel coils are used in the production of springs, suspension components, and other mechanical components, where their strength and durability are essential for reliable performance.

- Brake Systems: Stainless steel coils are used in brake systems, where their corrosion resistance and high temperature tolerance ensure the reliability and safety of braking components.

Conclusion

Stainless steel coils play a crucial role in the automotive industry, providing a combination of strength, durability, and corrosion resistance that make them essential components in a wide range of applications. Their versatility and benefits make them the material of choice for many automotive manufacturers, contributing to the performance, reliability, and safety of vehicles on the road.

FAQs

Q: Are stainless steel coils more expensive than other materials used in the automotive industry?

A: While stainless steel coils may have a higher upfront cost compared to some other materials, their durability and longevity often make them a cost-effective choice in the long run due to reduced maintenance and replacement costs.

Q: Can stainless steel coils be recycled?

A: Yes, stainless steel is a highly recyclable material that can be melted down and reused in the production of new automotive components, making it a sustainable choice for manufacturers.

Q: What are the main factors to consider when choosing stainless steel coils for automotive applications?

A: When selecting stainless steel coils for automotive use, factors to consider include corrosion resistance, strength, temperature tolerance, and weight, as well as cost and environmental impact.

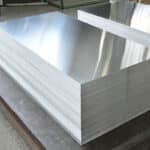

Stainless Steel Plate

Stainless Steel Plate

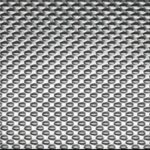

Steel Plate Punching

Steel Plate Punching

Pattern Steel Plate

Pattern Steel Plate

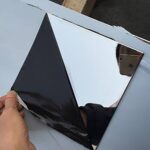

Mirror Steel Plate

Mirror Steel Plate

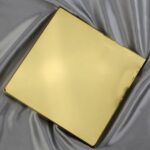

Colored Steel Plate

Colored Steel Plate

Stainless Steel Coil

Stainless Steel Coil

Stainless Steel Strip

Stainless Steel Strip

Angle Steel

Angle Steel

Steel Wire

Steel Wire

Round Steel

Round Steel

Channel Steel

Channel Steel

Flat Steel

Flat Steel

H-section Steel

H-section Steel

Round Pipe

Round Pipe

Square Pipe

Square Pipe

Rectangular Pipe

Rectangular Pipe