Stainless steel coils have long been the preferred choice for food processing equipment due to their unique properties and advantages. In this article, we will explore why stainless steel coils are the preferred choice for food processing equipment and why they are considered the best option for this industry.

Advantages of Stainless Steel Coils

Stainless steel coils offer a wide range of advantages that make them the ideal choice for food processing equipment. Some of the key advantages include:

- Corrosion Resistance: Stainless steel coils are highly resistant to corrosion, making them ideal for use in food processing equipment where exposure to moisture and acidic foods is common.

- Hygiene: Stainless steel is non-porous, making it easy to clean and resistant to bacteria growth, making it an ideal choice for food processing equipment where cleanliness is paramount.

- Temperature Resistance: Stainless steel coils can withstand high temperatures, making them suitable for use in food processing equipment that requires heating or cooling.

- Durability: Stainless steel is a durable material that can withstand heavy use and is resistant to wear and tear, making it a cost-effective choice for food processing equipment.

- Aesthetics: Stainless steel has a sleek and modern appearance, making it a popular choice for food processing equipment that is on display in commercial kitchens.

Applications of Stainless Steel Coils in Food Processing Equipment

Stainless steel coils are used in a wide range of food processing equipment, including:

- Food mixers

- Food dryers

- Food packaging machines

- Food heating and cooling units

- Food storage tanks

These are just a few examples of the many applications of stainless steel coils in food processing equipment.

Conclusion

Stainless steel coils are the preferred choice for food processing equipment due to their corrosion resistance, hygiene, temperature resistance, durability, and aesthetics. These coils are used in a wide range of food processing equipment and offer a variety of advantages that make them the ideal choice for this industry.

FAQs

What type of stainless steel is best for food processing equipment?

The best type of stainless steel for food processing equipment is typically 300 series stainless steel, which is highly corrosion-resistant and suitable for use in environments where exposure to moisture and acidic foods is common.

How do I clean stainless steel coils in food processing equipment?

To clean stainless steel coils in food processing equipment, simply wash them with warm water and mild detergent. Avoid using harsh chemicals or abrasive cleaning pads, as these can damage the stainless steel surface.

Are stainless steel coils more expensive than other materials?

While stainless steel coils may have a higher upfront cost compared to some other materials, they are often more cost-effective in the long run due to their durability and resistance to corrosion, which can help reduce maintenance and replacement costs over time.

Stainless Steel Plate

Stainless Steel Plate

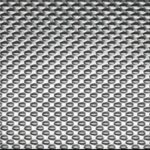

Steel Plate Punching

Steel Plate Punching

Pattern Steel Plate

Pattern Steel Plate

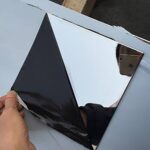

Mirror Steel Plate

Mirror Steel Plate

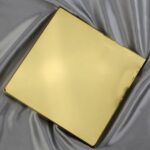

Colored Steel Plate

Colored Steel Plate

Stainless Steel Coil

Stainless Steel Coil

Stainless Steel Strip

Stainless Steel Strip

Angle Steel

Angle Steel

Steel Wire

Steel Wire

Round Steel

Round Steel

Channel Steel

Channel Steel

Flat Steel

Flat Steel

H-section Steel

H-section Steel

Round Pipe

Round Pipe

Square Pipe

Square Pipe

Rectangular Pipe

Rectangular Pipe