Category: Stainless Steel Plate Series

Factory spot stainless steel 304 201 316L 310S stainless steel plate, drawable mirror size Kaiping

Stainless steel plate, custom tie, laser cutting, CNC cutting, mirror, wire drawing, titanium processing

Non-magnetic 316 and 316L stainless steels (316L stainless steel properties see after) are molybdenum containing stainless steel species. The molybdenum content in 316L stainless steel is slightly higher than that in 316 stainless steel. The maximum carbon content of 316L stainless steel is 0.03. It can be used in applications where it can not be annealed after welding and where maximum corrosion resistance is required. Nominal composition: 316L 00CR17NI12MO23040CR18NI9 from which the chemical composition is different. The performance also has the very big difference, concrete you want what, the place difference also must check the data. 304 steel is resistant to sulphuric acid, phosphoric acid, formic acid, urea and so on. It is suitable for general water, gas, wine, milk, CIP cleaning fluid and other occasions with little or no corrosive materials. The addition of molybdenum element to 304 can improve the intergranular corrosion resistance, oxide stress corrosion resistance and reduce the hot cracking tendency of 316L steel. And good resistance to chlorination and corrosion. Commonly used in pure water, distilled water, drugs, soy sauce, vinegar and other high health requirements, medium corrosion, strong corrosion performance occasions. The price of 316L is almost twice that of 304mechanical properties 304 is superior to 316L stainless steel can be broadly classified by use, chemical composition and metallographic structure. The austenitic steel is composed of 18% cr-8% Ni, and the addition of each element is different. Classification by chemical composition: < URL > Series: Ferrite series, martensite series 2.CR-NI series: Austenite series, abnormal series, precipitation hardening series.

Contact us Form

"*" indicates required fields

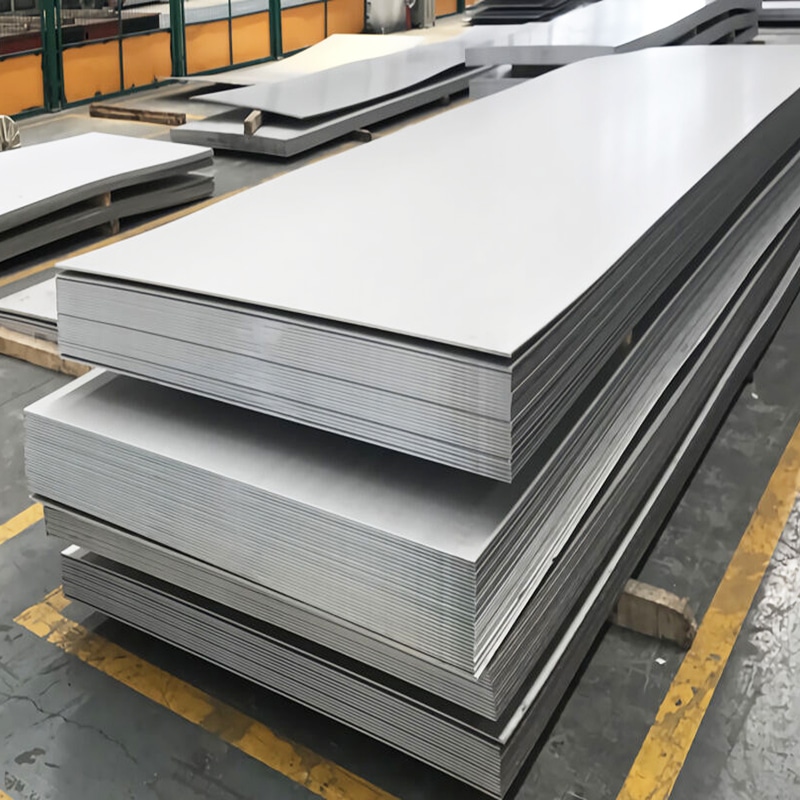

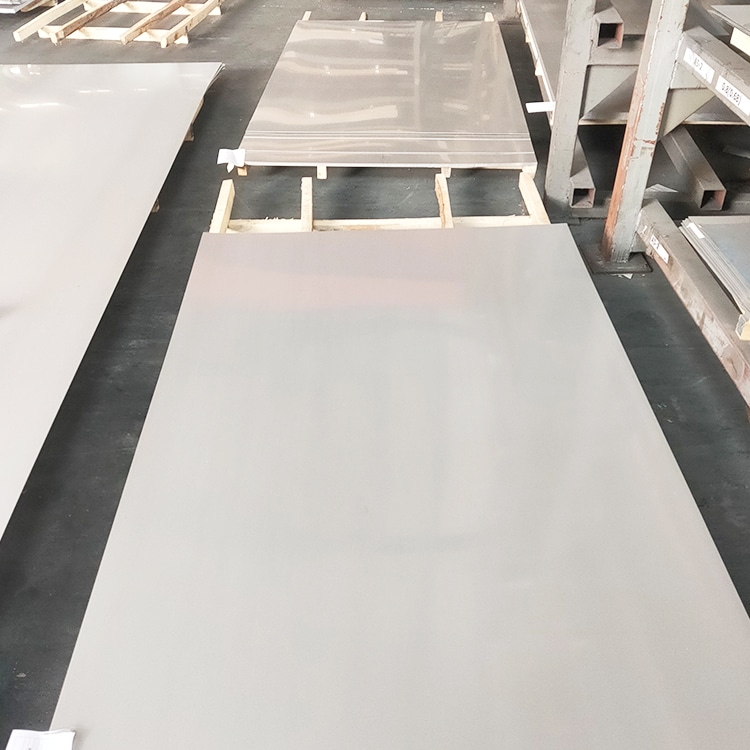

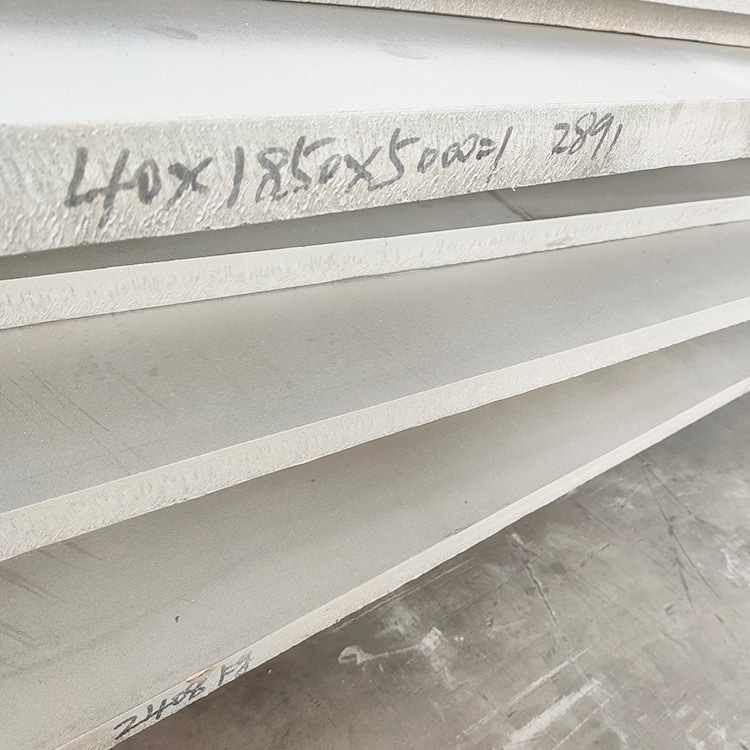

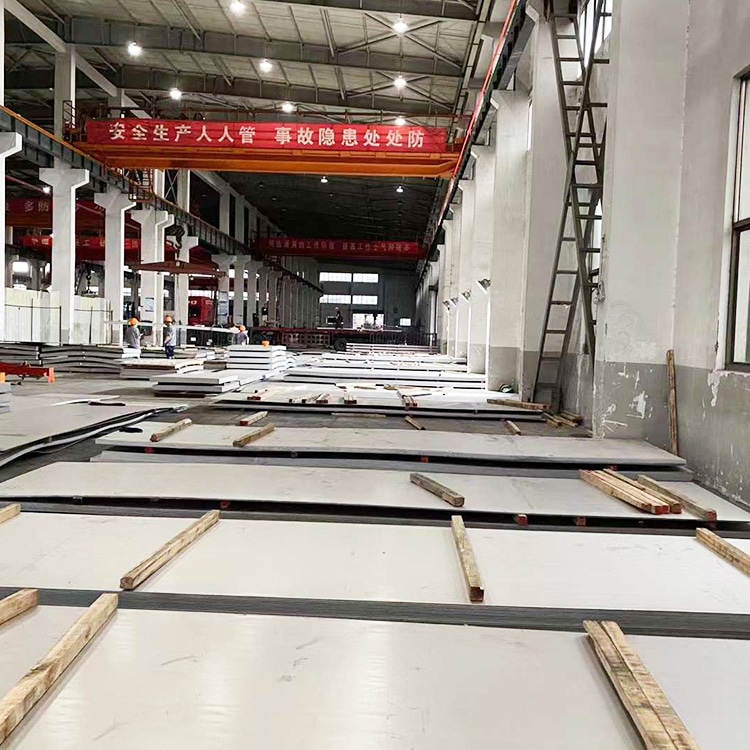

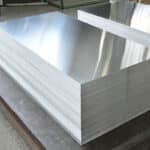

Stainless Steel Plate

Stainless Steel Plate

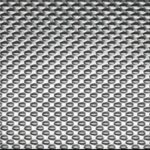

Steel Plate Punching

Steel Plate Punching

Pattern Steel Plate

Pattern Steel Plate

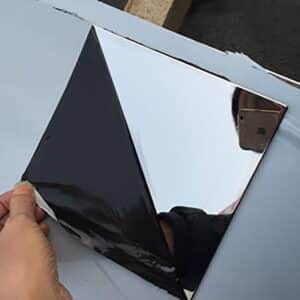

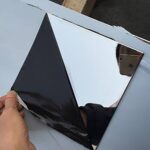

Mirror Steel Plate

Mirror Steel Plate

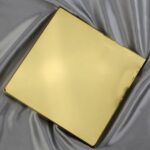

Colored Steel Plate

Colored Steel Plate

Stainless Steel Coil

Stainless Steel Coil

Stainless Steel Strip

Stainless Steel Strip

Angle Steel

Angle Steel

Steel Wire

Steel Wire

Round Steel

Round Steel

Channel Steel

Channel Steel

Flat Steel

Flat Steel

H-section Steel

H-section Steel

Round Pipe

Round Pipe

Square Pipe

Square Pipe

Rectangular Pipe

Rectangular Pipe